Hardware Bloat: The negatives of shoehorning equipment into a system.

By Baer Halvorson, Security Systems Engineer at Kenton Brothers

As an engineer, I look at photos of doors every single day. I zoom, I scroll, I furrow my brow, I scoff, I even take an immediate coffee break at the sight of some doors. Implementing security is a never-ending song of “just when you think you’ve seen it all…” One thing I want to highlight for a brief moment is a very specific problem that isn’t normal, but is common.

As an engineer, I look at photos of doors every single day. I zoom, I scroll, I furrow my brow, I scoff, I even take an immediate coffee break at the sight of some doors. Implementing security is a never-ending song of “just when you think you’ve seen it all…” One thing I want to highlight for a brief moment is a very specific problem that isn’t normal, but is common.

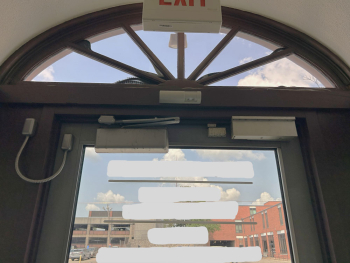

The door pictured is a perfect example of how time, multiple integrators, changing needs and the lack of system sterilization can cause problems. Shoehorning as much hardware as possible onto a door to fit the current need without proper removal of unnecessary devices creates a couple of major issues. Let’s break down how this happens by identifying what causes this problem; we’ll define system sterilization and its importance in the life-cycle of physical security systems and then we’ll address what to do to be smart and thorough in protecting the future of these systems.

The Setback

Not often enough do system integrators in the physical security space or clients needing security take into consideration the life-cycle of the system. There is no problem identifying the need, the integrator can easily identify the hardware for the moment and initial set up/billing are all very fluid processes in our industry. It’s only when you get to higher-level, usually enterprise systems, that the conversation of life-cycle comes into play. When this isn’t discussed in a medium to small security system, time can end up altering door design and the system itself can shift its purpose.

For example, perhaps the parking lot gets re-designed and now a door isn’t optimal for employee entry. Maybe the hardware takes a beating and the problem surrounding a device won’t resolve easily so the integrator pitches a different solution. All of this can lead to a door like the one pictured having hardware bloat, multiple locking devices, overlapping systems and more. The greatest threat posed by this issue is that there are now two to three times the amount of failure points and this door could end up easily compromised or become a burden to the system.

For example, perhaps the parking lot gets re-designed and now a door isn’t optimal for employee entry. Maybe the hardware takes a beating and the problem surrounding a device won’t resolve easily so the integrator pitches a different solution. All of this can lead to a door like the one pictured having hardware bloat, multiple locking devices, overlapping systems and more. The greatest threat posed by this issue is that there are now two to three times the amount of failure points and this door could end up easily compromised or become a burden to the system.

System Sterilization

The single greatest way to combat the issue of hardware bloat is system sterilization.

System sterilization is when a door needs to change for system purposes and security integrators remove the old defunct hardware from the site. This might incur more cost than leaving hardware on the door because you’ll need to patch holes, cover cuts, and repair frames to satisfy aesthetics. Often, because of this cost, the choice is made to leave the existing hardware even though you’re installing a new solution. This might not seem like a big issue for one door but over time, if obsolete devices are left in the field, you end up with a system that begins to become difficult to service and confusing to manage.

If a security manager or business owner audits their security program regularly, they can incorporate system sterilization and make sure that the system is running as lean as possible. This will cut time and save money in troubleshooting, and also satisfy the aesthetic of the space. When system sterilization is considered, the life-cycle of the physical security system is improved and lengthened providing better overall security and cost savings for its users.

Future Avoidance

There are a couple ways to make sure that access control, video surveillance and intrusion systems are avoiding the issue of hardware bloat.

There are a couple ways to make sure that access control, video surveillance and intrusion systems are avoiding the issue of hardware bloat.

The responsibility falls first to the customer’s security integrator; they are being paid to not just provide hardware but provide security solutions. The next person the responsibility falls on is the individual in charge of managing the system. Between the two of them, the integrator and system manager, they should be asking these three questions at every audit or change to the system:

- Is there any hardware installed in the field that is not in use?

- Are there any areas that have redundant devices that don’t call for it? (Redundancy is not to be avoided but appropriately implemented.)

- Are there solutions implemented within the system that are overkill?

Conclusion

Understanding that hardware bloat can slowly creep into a system and cause issues is the first major step to making sure that a physical security system is serving its purpose. Knowing what system sterilization is and how it can extend the life-cycle of a system will improve overall security and help provide financial savings. It’s important to keep an eye on this at every audit and/or change to the system and asking how the system can be further sterilized. Applying this to physical security systems will help keep the world a safer place which is the ultimate goal of physical security!

If hardware bloat is a problem for your business, and you’re not sure how to clean it up, we can help. Give us a call!

Leave a Reply

Want to join the discussion?Feel free to contribute!